Flexim

Leading Non-Intrusive, Clamp-On Ultrasonic Flow Meters for Liquids, Gases, and Steam

Leading Non-Intrusive, Clamp-On Ultrasonic Flow Meters for Liquids, Gases, and Steam

From liquids to gases, Emerson’s Flexim non-intrusive, clamp-on ultrasonic flow measurement and refractometer technologies measure virtually anything that flows. Innovative technology and accuracy makes us an industry leader in flow measurement solutions. Clamp-on FLUXUS® flow meters dependably measure the flow of almost all fluids, whether liquid or gas, and excel in measuring steam, without interrupting operations. The WaveInjector® mounting fixture can operate in extreme temperatures, extending the application range of non-intrusive ultrasonic technology to temperatures from -200 to +630 °C (-328 to +1166 °F). And our measuring instruments designed for use in explosive environments, ensure accuracy, safety, and reliability in all conditions.

What do you need to measure?

Non-Intrusive Ultrasonic

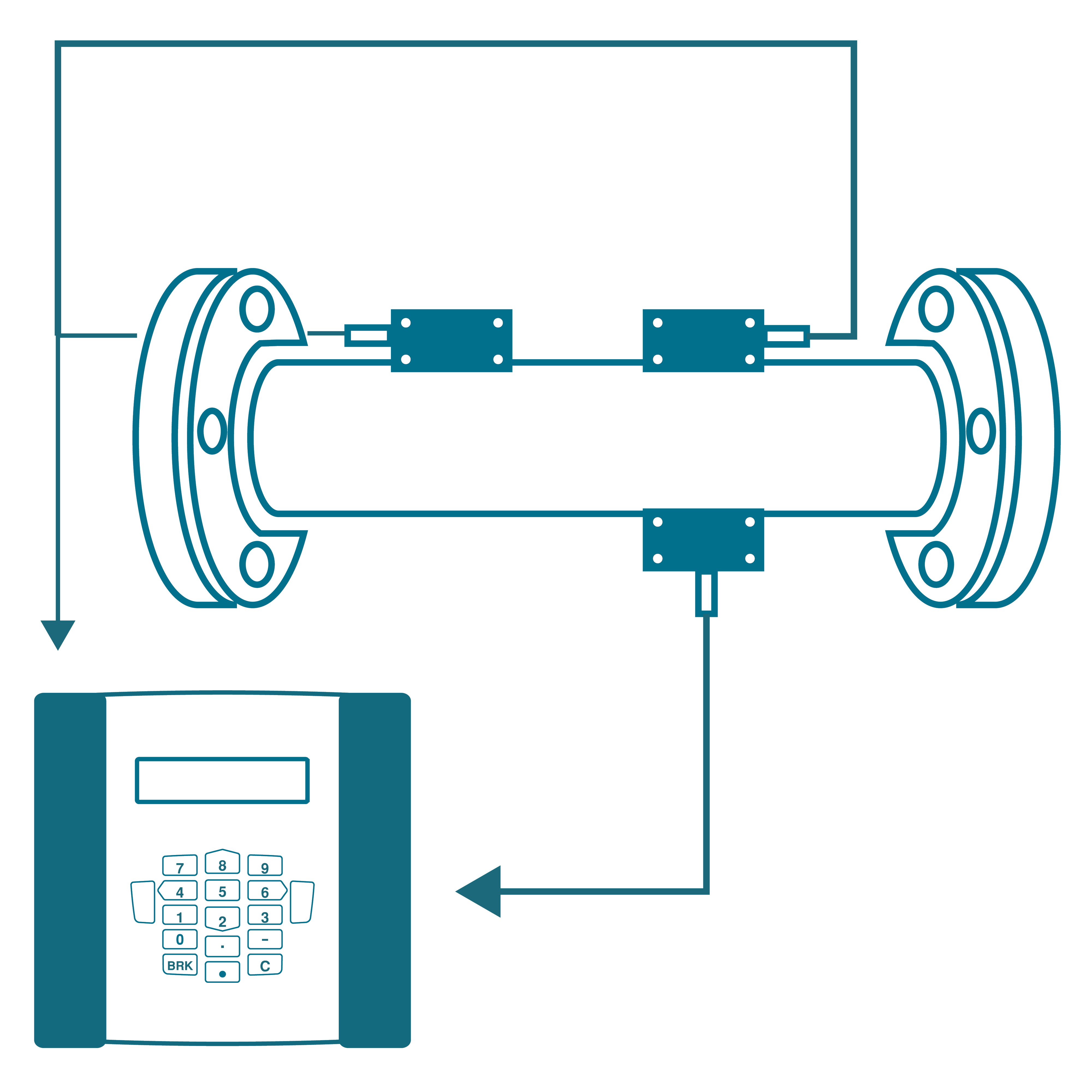

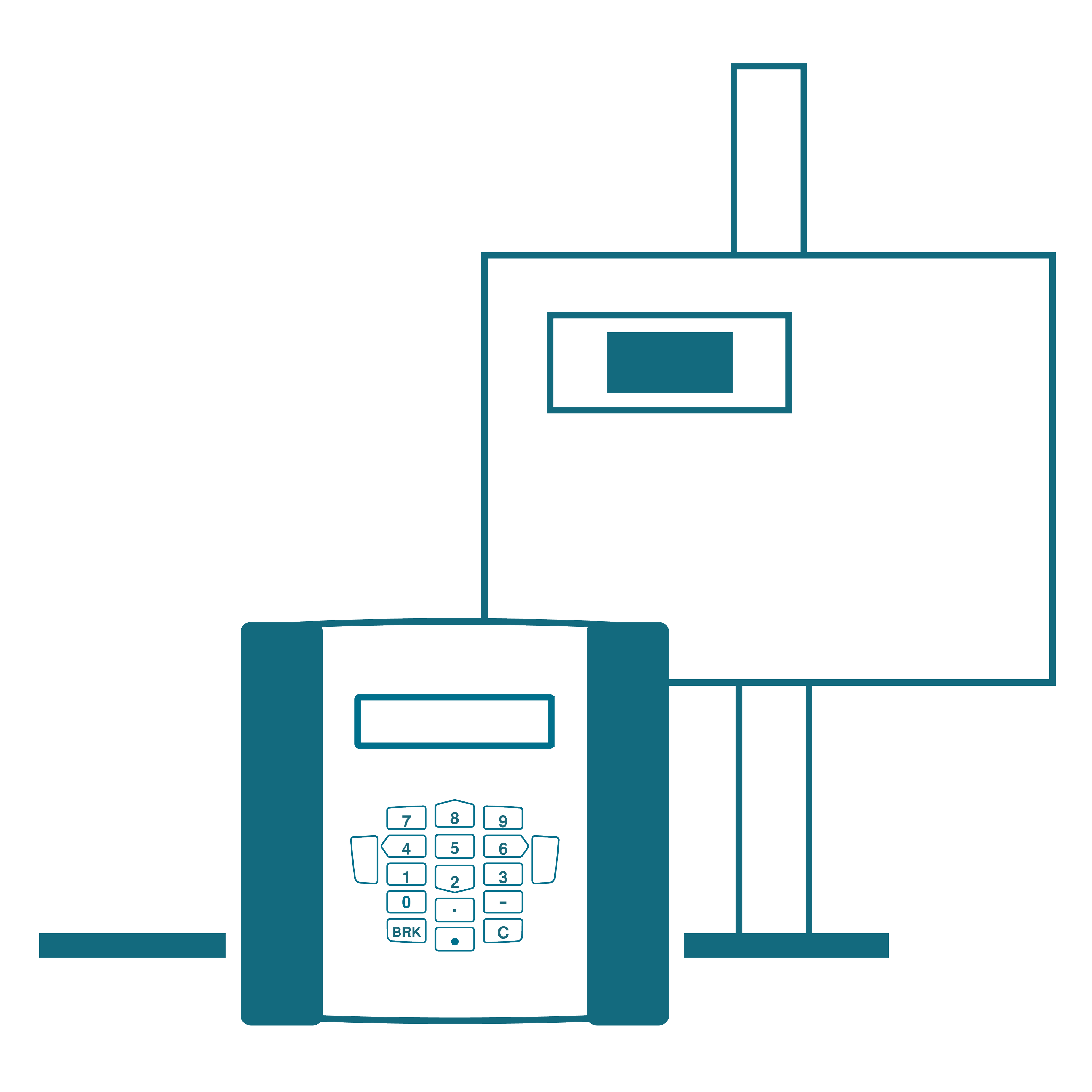

Non-intrusive, clamp-on ultrasonic flow meter: Accurate measurement without direct contact to the process

Process Refractometers

Process Refractometers: Monitor fluid composition for crucial quality control in industries like food and pharmaceuticals

EASTMAN CHEMICAL

I think we can safely say that ultrasonic flowmeters have finally met their potential. I have taken more than 600 readings with the FLEXIM portable meter, and my success rate is 99.8 percent; and that includes pipes containing acids, water, gasses, and slurries at several hundred degrees. At the end of the day, I collect all the data dumps from the built-in data logger and export it to my spread sheet program.

Greg H.

Process Analytics Chemist

NOVA Southeastern University

Now I can accurately put our settings exactly where the factory recommends for optimum performance. But there’s more to it than that. Since our pumps have frequency drives, we can stop running them at full speed. Before the FLEXIM meters, we used butterfly valves and gate valves to back down flow. Now I’m able turn every valve wide open and program the frequency drive to run at the optimum speed to deliver the cooling water.

Jim M.

HVAC Engineer

Mosaic

We now have 20 FLEXIM PIOX ultrasound meters performing well and sending data back in real time. They have improved safety, accuracy and production. I’m pleased at how non-intrusive metering makes my job easier and the plant more efficient by reducing downtime. Before, we couldn’t repair acid leaks on the run because we couldn’t operate without a concentration meter.

Chris H.

Sulfuric Acid Superintendent

Eastern Reservoir Services

It soon became apparent that clamp-on ultrasonic metering was the way to go. I researched all of the meters available and narrowed it down to FLEXIM. We had a few meters in for demonstrations and it won out because it had the features we needed, including a 16-hour battery. It was also the most intuitive and fast to install.

Bram A.

ERS Field Engineer

Empire State Building

As the building efficiencies continue we also utilize FLEXIM energy meters to upgrade old or non-existent submetering throughout the building. These meters have proven reliable and are perfect for retrofit installations because they are nonintrusive and eliminate the need to cut into piping for installation.

Dennis P.

Program Manager

Coastal Monitoring Associates

The new FLEXIM system gives us a more stable system than we had. And the accuracy has been excellent.

Ron P.

Hydrologist (CMA)

Manager Jacksonville Water District

We had a serious balancing issue. Our measurements showed we were delivering significantly more water than we were taking from our wells. The problem was the magnetic flowmeters, due to the high mineral content the probes were becoming fouled degrading the signal and reporting lower than actual flows. We found FLEXIM and after we proved through testing that the meter was 1% accurate we installed 35 meters on our most problematic well measurements.

Shawn A.

Manager

United Riverhead Terminal

We installed a FLEXIM HPI meter for flow and interface detection to improve our operations. We were losing money because we could not detect the exact moment when the product arrived from the barge so that we could divert it to the right tank. The HPI meter was successful in exactly identifying both of the interfaces. That information allowed us to minimize the amount of number two that was downgraded. The meter also provided accurate real-time rate and total volume of product and cutter movements. That saved us between 1,500 and 2,000 barrels which translates into $30,000 in savings. That should translate to an annual savings of $750,000.

Scott K.

Operations Manager

Aegis Energy Services

When we heard of FLEXIM's low flow capability, we gave it a try. The results were so accurate that we now use one in every application.

Dale D.

Sales and Marketing

Aquarion Water Company

FLEXIM meters have turned out to be better than the meters we were used to. The meters measure flow down to .03ft/sec which is 10 times lower than the Mag meters we use.

John S.

Senior Operations Specialist

University of Akron

We searched for a clamp on meter to measure 400˚F high temperature hot water. We found FLEXIM that was rated to 750˚F and put the first meter on our main line. We found out that the steam company was not billing us correctly, it turned out that the FLEXIM had a much better turndown than the other meter and was more accurate on low flow. Now we are completing most of our buildings with FLEXIM meters for our performance contract.

Dave M.

Mechanical Engineer/ Project Manager

Jacobs Engineering Group (World Trade Center)

Although it ended up being a big project, it could have been much worse. There was no damage to the pumps or the generators and downtime was significantly reduced.

Remon Y.

Commissioning Manager

Buckeye Petroleum Terminal

We needed flow measurement for pipeline leak detection. I knew I wanted a flowmeter that was nonintrusive and highly accurate with a solid operational history to communicate to our control system. We selected FLEXIM's 4-path meter for this highly sensitive flow measurement. The accuracy has met Buckeye’s needs and satisfied the Coast Guard’s oversight requirement during marine discharge activities. We have been up and operating for more than a year and there have been no issues. One nice thing about the ultrasonics is that if there is an issue, they are easy to access to make any changes. But, since there are no moving parts, I don’t see any issues in the future.

David M.

Senior Project Manager

Cardinal Gas Storage

We invested in 3 different types of GE ultrasonic meters, insertion and clamp-on. We had issues and paid for GE technicians to get these meters working. My company decided to not throw any more money at the GE meters and we just abandoned them all together. We had 8 of them at one facility and 5 of them at the other. Once we found FLEXIM, we put it right beside the GE meters and tested it for 1 yr. I can honestly tell you I've never had to come back to it due do flows errors. We now have them all over our three facilities. I put these FLEXIM meters on everything.

Justin P.

I/E Manager

Ameren Gas Storage

We have about 100 FLEXIM meters installed at numerous storage fields. We have been very pleased with the accuracy and reliability. We have also been pleased with the service and knowledge of the representatives.

Max F.

Supervisor

Utilivisor Continuous Energy Monitoring

We always specify FLEXIM meters because their accuracy is 1% of rate backed up with a calibration certificate. More importantly they maintain their accuracy at low flow rates. FLEXIM meters capture low flow rates better than any meter I have encountered. If the flow rates aren’t detected you are giving away free energy.

Tim A.

Manager

Crestwood Midstream

Utilizing clamp-on ultrasonic [FLEXIM] meters really improved our profitability. I was surprised the meters handled just about everything we threw at them. They were far more robust and accurate than I thought they would be. This is a capability every midstream operations manager should have.

Mike H.

Director of Operations

NASA

FLEXIM is selected as the preferred meter; this predicated on investigations including technology search, market survey, technology familiarization, unit familiarization, expected accuracy analysis, and actual field testing. Independent testing by KSC and CEESI laboratories confirms the 1% accuracy specification of FLEXIM.

Michael K.

URS Corporation for NASA

Major East Coast Power Generator

Now that, with FLEXIM, the tube and flow problems on the unit have been resolved, we plan to move forward with a similar solution for a sister unit. We're sure with what we've learned, we will be able to get accurate flow readings right away.

Tim

Chief Engineer

Mid-Atlantic Chipmaker

The FLEXIM meter we chose was portable and worked on all the pipe sizes. It also measured slow flows very accurately. We've been going to each lateral and totaling the flow over a particular period of time. Then we compared that to the tool's mass flow meters. When we compared the performance to our own buildings flowmeters, the FLEXIM meter was quite accurate.

Anne

Professional Engineer

Major Northeast State University

We decided to put one [FLEXIM] meter on our chemistry building, which had been a problem for us. We agreed to a trial period on both chilled and hot water that reached up to 350°F. The measurements were within one percent with no drift. It finally gave us accurate data on that building that we had been lacking. Given that success, we began replacing our differential flow meters with the ultrasonics. We now have a total of about 100 ultrasonic meters monitoring our HVAC flow and temperature and reporting to our dashboard/BAS system. We recently added 70 new meters for domestic water, and we continue to expand building by building.

Tim

Energy & Sustainability Manager

Midwestern Aluminum Plant

I proposed another FLEXIM meter for the hot water line. After our experience with the FLEXIM portable, I had no problem getting approval to purchase a permanent clamp-on FLEXIM liquid meter to measure flow and temperatures to and from the plant.

Mark

Utilities Engineer

Silicon Valley Technical Center

The FLEXIM Meters worked out well for SVTC. They were not as close to capacity as they thought. Replacing aging equipment and perform upgrades and retrofits was going to be expensive, but there was no need. This project more than paid for itself.

Jason D.

VP of Engineering

Easterly Wastewater Treatment Plant

The installation of the meters went smoothly. They have provided consistent, reliable data. In the future, the data will be used by the process control and automation system to not only monitor, but possibly control the flow and optimize the process.

Paul M.

Senior Project Engineer

Phenol Plant

The differential meter was a lot more noisy; it read higher flow than the FLEXIM. And the measurements would drop over time as it plugged. The ultrasonic gave us good, flat readings with minimal noise. For three months we tested it and then installed it permanently. It is now one of the plant’s safety interlocks and it is still giving accurate, noise-free measurements. And we don’t have to take it out and clean it!

Mike

Reliability Engineer

No contact with the media and no risk of leaks

No drilling and no interruption to operations

Independent of fluid, pipe material and diameter

By selecting a new country/region, product(s) may be unavailable and items in your shopping cart will be removed. Please contact us for assistance.