Flexim

Leading Non-Intrusive, Clamp-On Ultrasonic Flow Meters for Liquids, Gases, and Steam

From liquids to gases, Emerson’s Flexim non-intrusive, clamp-on ultrasonic flow measurement and refractometer technologies measure virtually anything that flows. Innovative technology and accuracy makes us an industry leader in flow measurement solutions. Clamp-on FLUXUS® flow meters dependably measure the flow of almost all fluids, whether liquid or gas, and excel in measuring steam, without interrupting operations. The WaveInjector® mounting fixture can operate in extreme temperatures, extending the application range of non-intrusive ultrasonic technology to temperatures from -200 to +630 °C (-328 to +1166 °F). And our measuring instruments designed for use in explosive environments, ensure accuracy, safety, and reliability in all conditions.

What do you need to measure?

Flexim manufactures high-quality measurement instruments and offers technical and consulting services. We offer on-site measurements, lab analysis, project handling, training, commissioning, rentals, and expert consulting.

FLUXUS non-intrusive flow meter installation is easy, but technicians can help with challenging setups. Proper placement ensures accurate readings, and we offer consulting, system setup, testing, and installation acceptance.

Flexim offers scalable on-site flow measurement, from single-point checks to full audits. Even in hazardous areas, we measure liquid, gas, energy, and compressed air flows, and deliver equipment checks, and detailed reports.

Flexim's measurement systems are highly durable, but we check and maintain, reviewing systems, reading diagnostic data, and comparing results with reference systems. Recalibration is available at our in-house flow rig.

Flow assurance is vital in the Power Generation, Chemical, and Oil & Gas industries. Flexim’s portable, hazardous area flow meters for fire pump testing, detect leaks and monitor pump performance with no downtime.

Flexim’s recalibration ensures long-term flow meter accuracy. At ISO17025-certified labs in Berlin and New York, calibration is traceable to national standards. Clamp-on meters allow recalibration without service interruption.

Flexim offers a weekly-based rental service for clamp-on flow meters. Choose from models for standard, energy, or hazardous area measurements. Renting offers flexibility, and access to advanced equipment without high ownership costs.

Flexim’s product trainings by experienced engineers, ensure efficient clamp-on flow meter use. The training can cover gas flow measurement, regular system checks, or challenging setups, and can be held on-site or at our facilities.

Emerson's Flexim non-intrusive ultrasonic flow meters and liquid analyzers are used in a wide range of applications. Our application reports provide useful insights from the customer's perspective.

Visit our Software download center to download device drivers using our search wizard tool, to download the latest versions of your favorite applications software, and to gain access to your licensed software and applications.

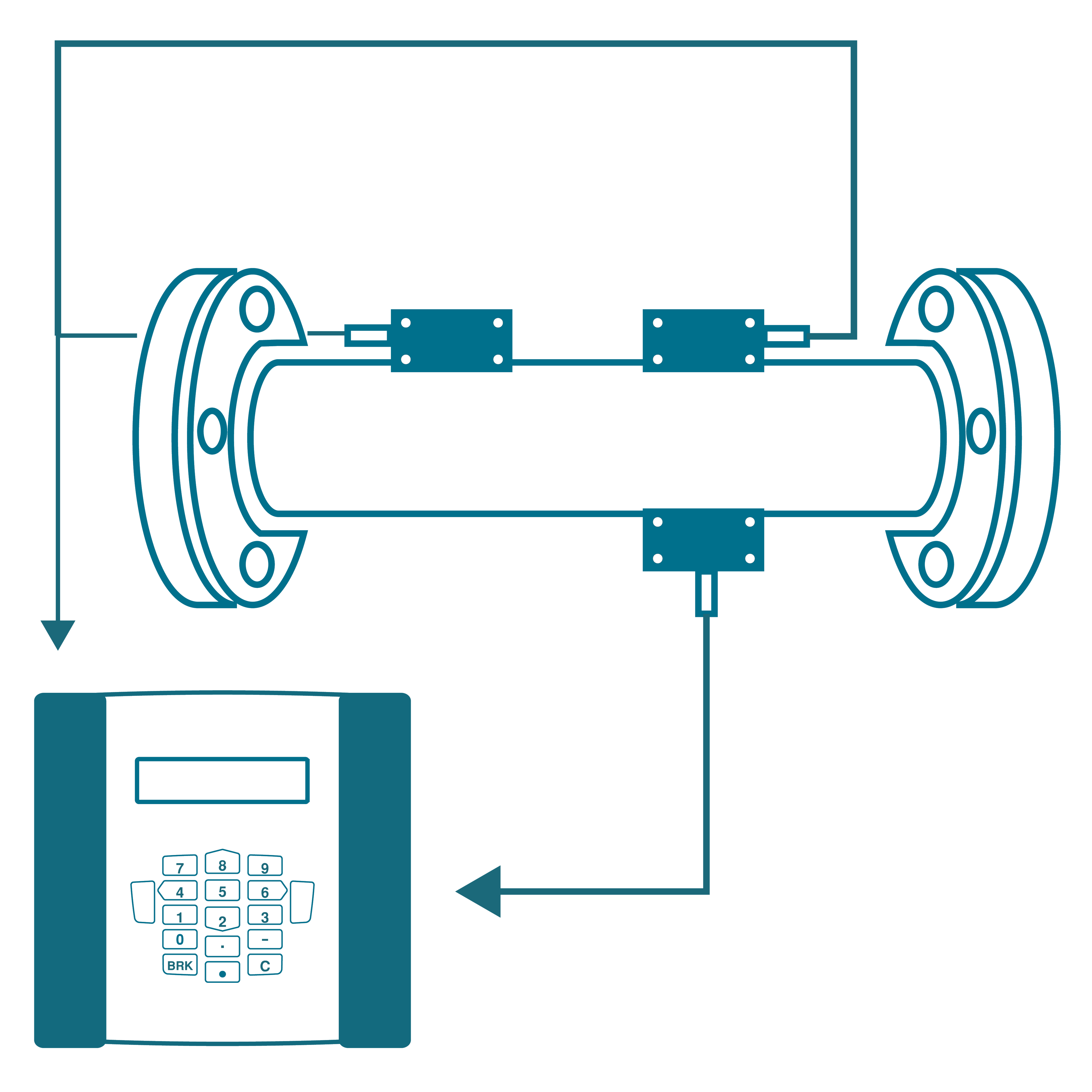

The FLUXUS ultrasonic systems measure the flow rate using the transit time difference method. Clamp-on ultrasonic sensors mounted on the outside of the pipe alternately send and receive signals in and against the direction of flow in the pipe. As the fluid in which the signals spread flows, the signals are carried along with it. This movement causes a shortening of the sound path for the signal in the direction of flow and a lengthening for the signal against the direction of flow. As a result, the transit times also change. The transit time of the signal in the direction of flow is shorter than that in the opposite direction. The transit time difference is proportional to the average flow velocity. Based on this, the measuring transducer calculates the volume flow by processing the pipe cross-section and the mechanical fluid parameters.

The measurement of the transit time difference is a pure time measurement. This can be realized with extreme accuracy. The uncertainty of our FLUXUS flow meters for the measured volume flow is typically 1% of the measured value, while the repeatability, which is crucial in many applications, is 0.15%.

With the FluxDiag software, Emerson | Flexim offers powerful software to precisely determine the uncertainty at the measuring point and to evaluate the measurement quality.

Emerson | Flexim is the only manufacturer of ultrasonic flow meters that calibrates transmitters and sensor pairs independently of each other and traceable to national standards. Only by doing so is it ensured that the specified measurement uncertainty is reliably maintained regardless of the combination of transducer and sensors.

In principle, yes. The only requirement for the functioning of flow measurement with externally mounted clamp-on ultrasonic sensors is that both the pipe wall and the medium flowing inside can be penetrated acoustically, i.e. measurement on partially filled pipes is not possible (or does not provide reliable measurement results). The ultrasonic sensors for liquids offered by Emerson | Flexim cover a pipe size range (internal diameter) from 0.24 to 256 in (6 mm to 6.5 m).

The powerful transmitters of the FLUXUS series as well as the broad sensor portfolio with both shear wave and Lamb wave sensors enable non-intrusive flow measurement even on challenging composite pipe materials such as PCCP and also on liquids with high solid or gas content. One of the main advantages of non-intrusive measurement technology in such challenging applications is that the feasibility can be checked directly on site without any disruption to plant operation.

No. A key feature of ultrasonic flow measurement technology is its extreme measurement dynamics. FLUXUS measures highly accurate flow velocities from 0.39 in/s to 82 ft/s (0.01 to 25 m/s) regardless of the flow direction, i.e. the measurement is bidirectional. Cross-sectional tapering, which may be necessary for wetted measurement methods that require a minimum flow, is no longer necessary.

No, FLUXUS can do much more. The primary variable measured by the FLUXUS flow meter is the difference in signal transit time in and against the direction of flow. This is a metric for the average flow velocity. The measuring transducer uses this to calculate the volume flow.

If the pressure and temperature - and therefore the density of the fluid - are constant in the process, the transmitter can also output the mass flow. If pressure and temperature change, these must be measured and fed into the transmitter via current inputs. FLUXUS then determines the mass flow from the volume flow and density non-intrusively.

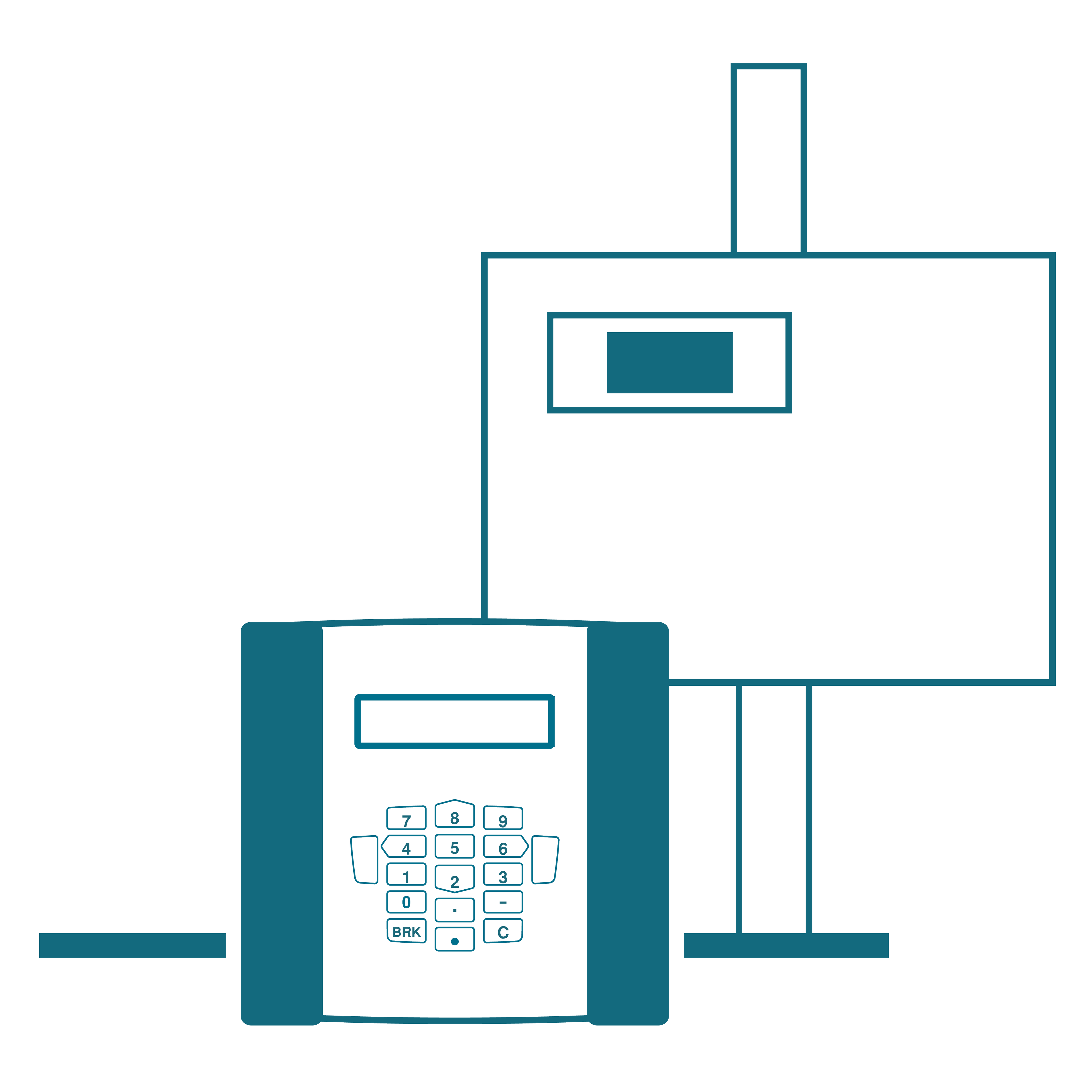

FLUXUS can also determine the heat flow in heat transfer processes. For this purpose, the temperature only needs to be recorded in the flow and return. The heat flow meters from Emerson | Flexim are called FLUXUS F TE.

Using the same measurement technology as for flow measurement - i.e. the clamp-on ultrasonic sensors mounted on the pipe - FLUXUS also simultaneously measures the sonic velocity in the fluid. This is a material-specific variable. Therefore, non-intrusive acoustic measurement technology is also suitable for process analysis purposes, such as media differentiation and media determination. The clamp-on ultrasonic analytical systems from Emerson | Flexim are called PIOX S.

No. Because the sensors do not come into direct contact with the medium, they are practically not subject to wear. Permanently stable coupling foils ensure the best acoustic coupling over the long term. For measuring tasks where accuracy is particularly important, Emerson | Flexim recommends regular checking of the measurement at 5-year intervals and possibly recalibration. The check can be carried out by our experienced service technicians on your premises.

No contact with the media and no risk of leaks

No drilling and no interruption to operations

Independent of fluid, pipe material and diameter