Rosemount Quad Vortex Technology

Offering world-class reliability in safety and critical measurements

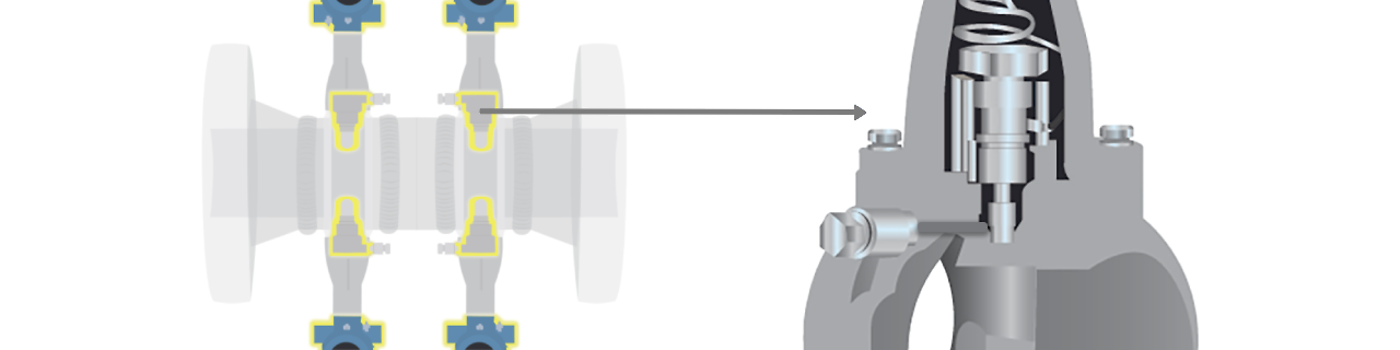

Compact, redundant design with a gasket-free, non-clog meter body, the Rosemount 8800 Quad Vortex Flow Meter features four independent transmitters and sensors, ensuring a safe and reliable solution and maximum process availability for redundant flow measurement.

For safety related measurements in SIS applications, Emerson’s Quad Vortex Flowmeter has redundant, independent sensors and transmitters which are critical for the prevention of common failure modes or spurious shutdowns especially in 2oo3 applications. The Quad operates on the principle of the Von Karman Effect. The proprietary shaped dual shedder bars act independently, producing an accurate and repeatable measurement.

The compact design reduces installation costs and pipe run requirements while providing a 2oo3 voting solution. It delivers accurate, redundant flow measurement using proprietary spaced dual shedder bars.

Guard against spurious trips using two out of three voting and a fourth integrated transmitter for process control. This all-in-one solution is certified to IEC 61508 and is capable for SIL 2 and SIL 3 installations.

Frequently Ask Questions

A: It is a fully redundant solution in a compact design which eliminates the need for additional flow meters and additional straight run, which reduces installation costs. With no impulse lines and a unique all-welded design, leak points are eliminated, and operating expenses decrease significantly. The cost of a false trip can be very expensive in terms of lost production and the cost of restarting the process. The Rosemount Quad Vortex delivers a reliable 2oo3 voting scheme, which keeps the process running until at least two out of the three transmitters respond to a trip simultaneously.

A: Emerson’s Rosemount Quad Vortex Flow Meter is certified for safety instrumented functions (SIFs) capable up to SIL 3. It is commonly used in Safety Instrumented System (SIS) loop applications, where equipment must meet the highest reliability standards while minimizing and/or eliminating unscheduled shutdowns. During the instrumentation decision process, the requirements document typically states what SIL level the product must meet. The Rosemount Quad Vortex was designed to meet reliability specifications while also providing a fully redundant solution to meet certification levels.

A: The Rosemount Quad Vortex is installed in several different industries like chemical, refining and power. In steam measurement where safety is critical and a reliable mass and energy balance is needed, the Rosemount Quad Vortex is utilized for its accuracy and dependability. The Rosemount Quad Vortex has been installed in numerous applications — hydrofluoric alkylation units, delayed coker heaters, feedwater flow in power plants, reformers in chemical plants, and more.

A: For simplified troubleshooting, device diagnostics allow for verification in the field of the flow meter’s electronics and sensor without process shutdown. The flow signal generator built directly into the electronics enables remote verification of the electronics. The sensor strength value is typically used to see the flow signal and provide further information about the filter settings and health of the sensor.

A: With such a simple installation consisting of bolting in, wiring up and turning on, installation time and costs are greatly reduced. As there are no moving parts, no calibration needed in the field, and no maintenance required, both time and money are saved with this solution.