Blue Hydrogen Valve, Regulator & Actuator Solutions

Advanced blue hydrogen production valve solutions for safer, smarter, more reliable and scalable operations.

With a vast portfolio of control, isolation, relief valves, regulators, and actuators, Emerson offers advanced solutions crucial for the success of blue hydrogen production. Our expertise drives your operations forward, helping you achieve low emissions, safety, and productivity goals.

Solutions that address the key blue hydrogen production challenges

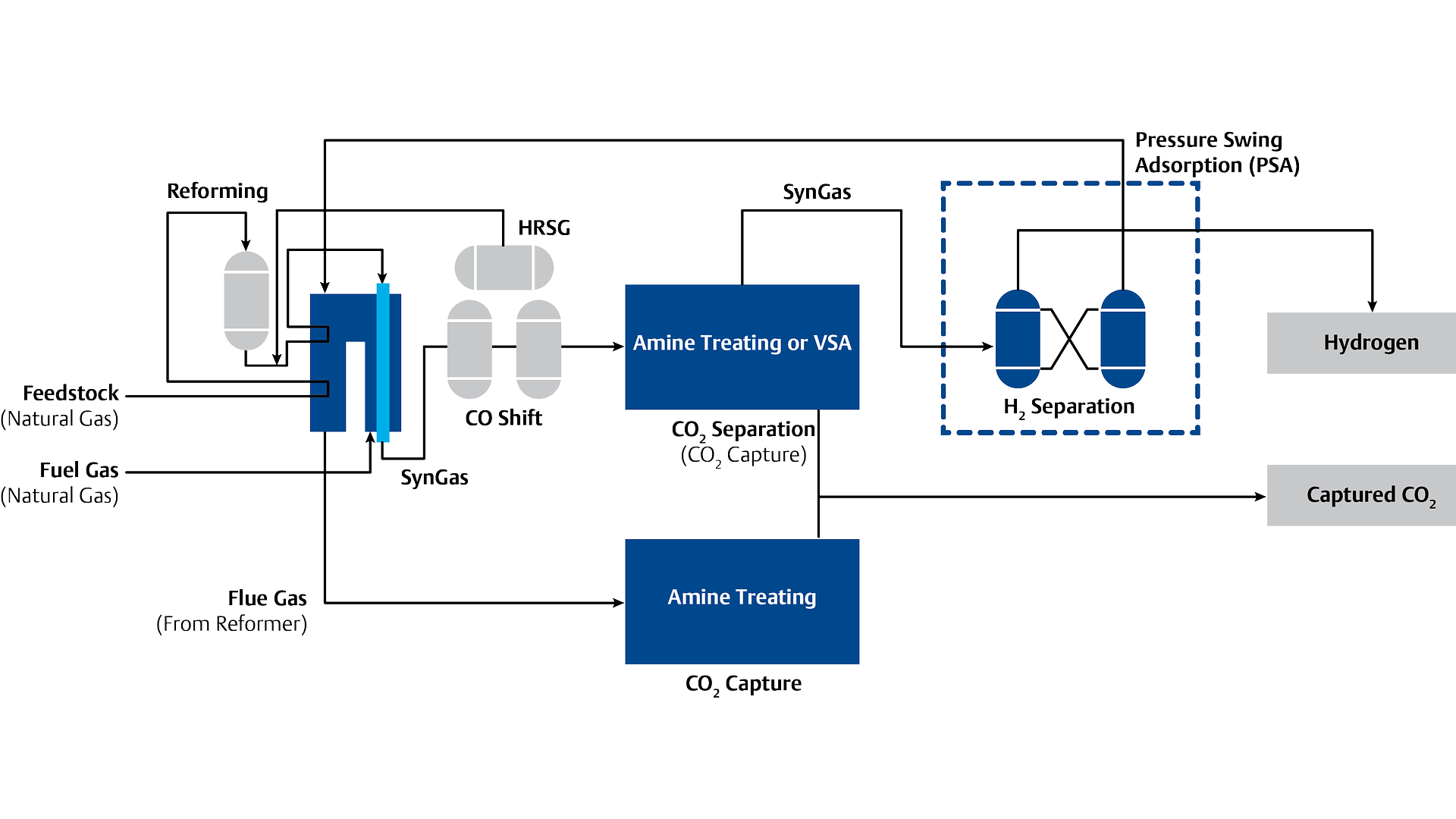

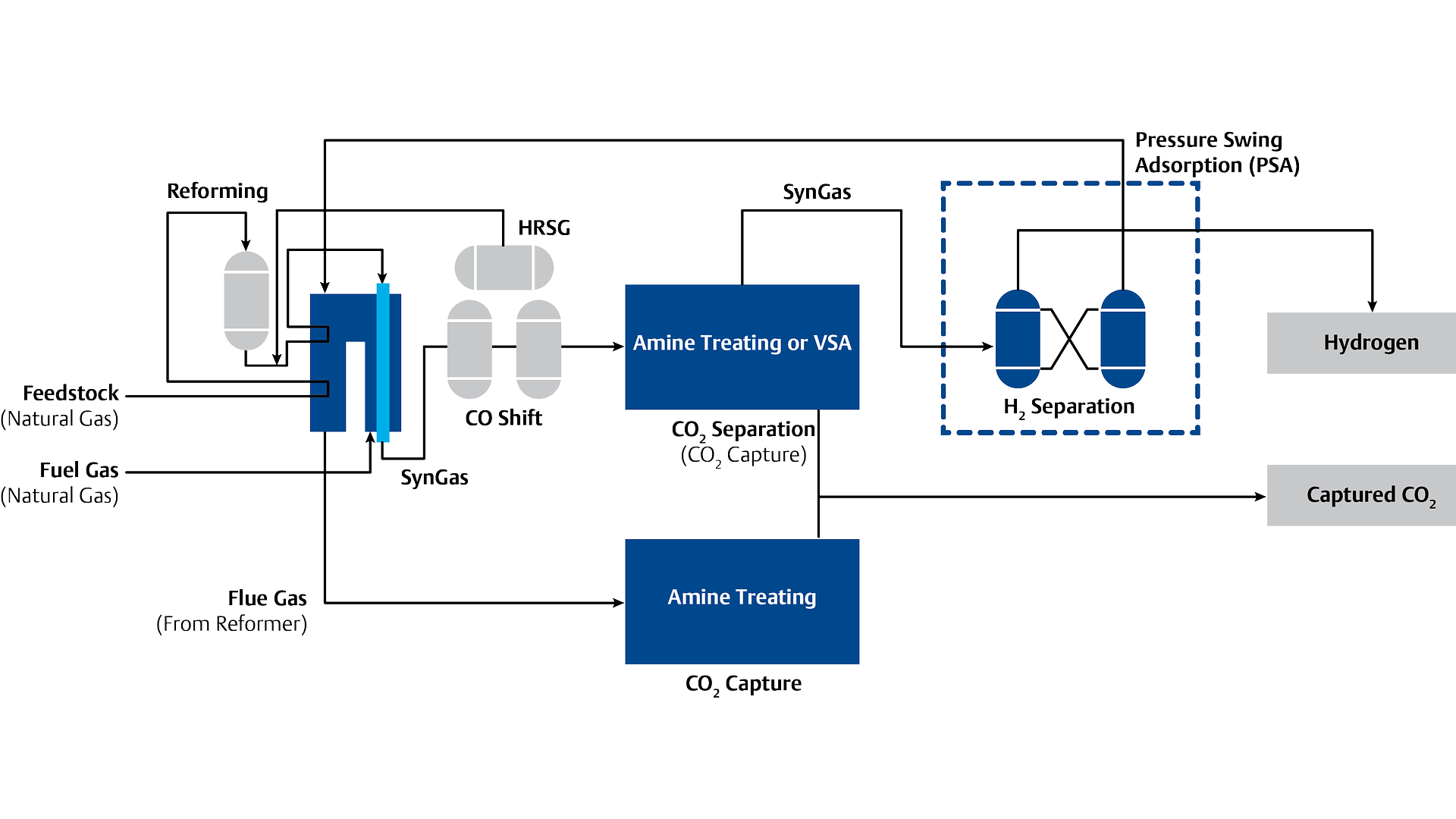

Emerson is a trusted partner and advisor to blue hydrogen producers. Find solutions for steam methane reformers (SMR), autothermal reformers (ATR), amine treatment, and pressure swing adsorption (PSA) for carbon capture and sequestration.

Natural gas reforming uses an advanced and mature process that builds upon the existing natural gas availability and infrastructure. In the United States, 95% of the hydrogen produced utilizes natural gas reforming to enable and meet the demand for hydrogen production. Emerson supports operators through advanced technologies in steam methane reformer, amine treatment and vacuum swing adsorption.

Anderson Greenwood Type 400 and 800 Safety Valves

Premium performance and advanced technology for overpressure protection.

Fisher™ GX Control Valve And Actuator System

Meet of flow & pipeline sizing requirements. The engineered passages within the valve body offer optimal capacity & a stable flow pattern for smooth operations.

Fugitive Emission Ball Valve

With limited capital, addressing the thousands of potential leak paths in your plant can seem like a daunting challenge.

Yarway™ Blowoff and Blowdown Valves

Prevent foaming or carryover of impurities & intermittent blowdown (or blowoff) in the boiler system. Maintain the boiler water quality within prescribed limits

Fisher™ Type 63EG Relief Valve or Backpressure Regulator

Liquid & gas services. Main valves use quick-change trim package for fast maintenance. Type 63EG is suitable for throttling backpressure & bypass applications.

Fisher™ EZH and EZHSO Series EZH (Spring-to-Close) and EZHSO (Spring-to-Open) Series Regulators

Pilot-operated, pressure-balanced, soft-seated regulators for high-pressure natural gas transmission/city gate stations, large-capacity distribution systems & power plant feeds

Operators using amine treatment to capture carbon face a trade-off between capture efficiency and energy cost to regenerate solvent. Emerson supports operators through advanced technologies to reach peak efficiency.

Anderson Greenwood Type 400 and 800 Safety Valves

Premium performance and advanced technology for overpressure protection.

Fugitive Emission Ball Valve

With limited capital, addressing the thousands of potential leak paths in your plant can seem like a daunting challenge.

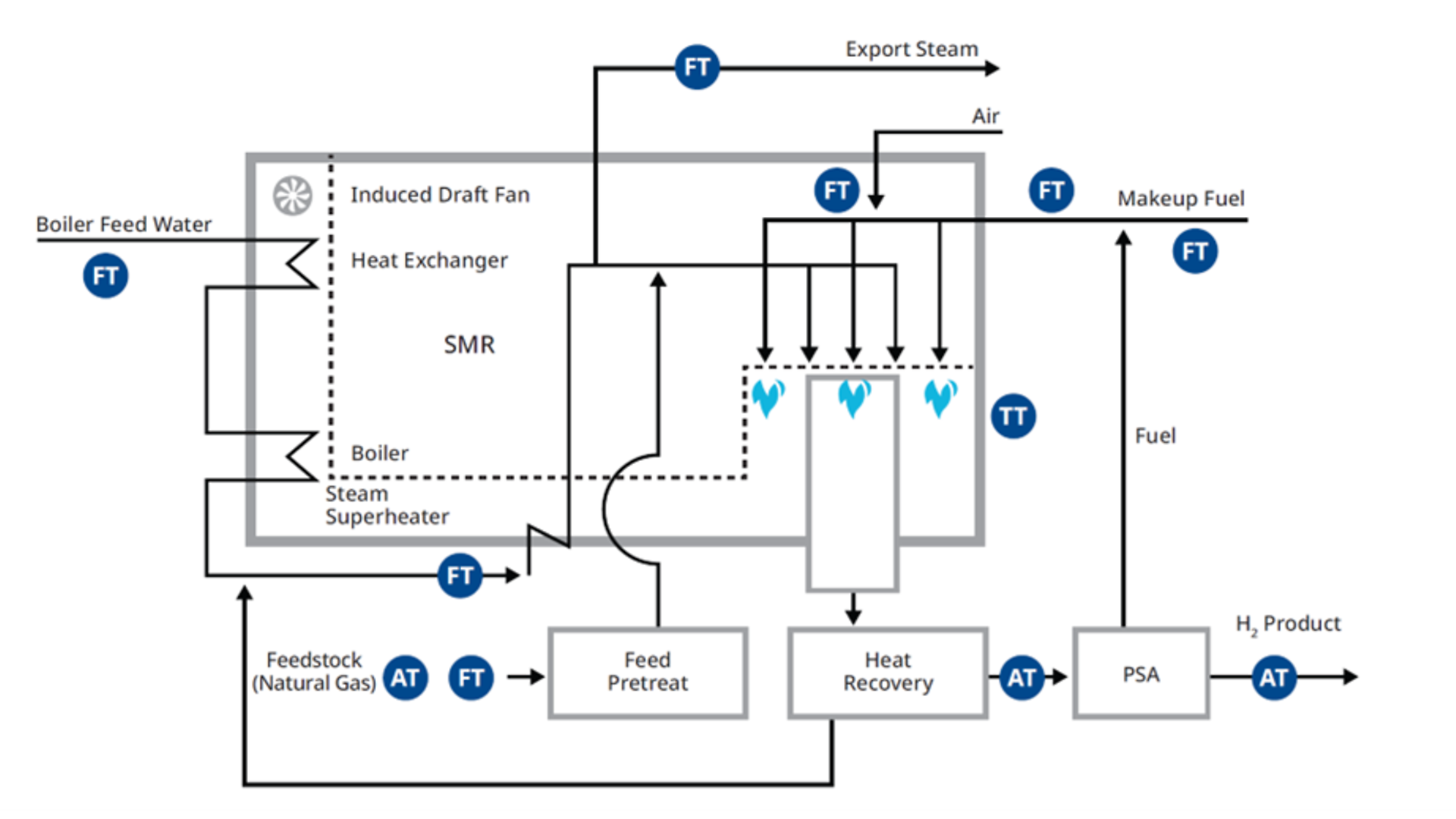

Pressure swing adsorption (PSA) cyclical process requires high levels of hydrogen purity to remove carbon dioxide from continuous gas streams. Using control and rotary valves along with gas analyzers, Emerson technologies ensure units operate reliably in critical high-cycle operations.

KTM Metal Seated Valve

The world’s first supplier of full-bore, split-body ball valves and pioneered soft- and metal-seated valves.

Fisher™ FIELDVUE™ DVC6200 Digital Valve Controller

The DVC6200 allows for your operation to run closer to setpoint, improving product quality with more accurate control.

Fisher High Performance Butterfly Valve and Control Valve and Actuator System

Keep pressure swing adsorption (PSA) units operating reliably without unplanned interruptions.

The Keystone K-LOK® Series 36/37

ASME Class 150 and 300 high-performance butterfly valve. Wafer, lugged & flanged. Seals at high & low pressures and dirty services

Electric Actuators

Zero-emission solutions with options for isolation & control valves. Our portfolio has innovative technologies developed by brands like Bettis™, Biffi™ & EIM™.

The Autothermal Reforming approach produces syngas (a mix of hydrogen, carbon monoxide, and carbon dioxide) that can be separated into individual streams. It interfaces well with CCS technologies and is valued for its cost-effectiveness.

Boiler Level Gauge - Penberthy TSL

Penberthy TSL level gauge with special orientation and configuration for use specifically in steam applications.

Electric Actuators

Bettis™ XTE3000 is an intelligent multi-turn electric actuator designed to meet the valve automation demands of the Oil & Gas, Power & Process Industries.

Carbon Capture with PSA

Fisher™ GX valve & actuator system meets a wide range of flow and pipeline sizing requirements. A 3-way construction is suited for accurate temperature control.

Pneumatic Actuators

Bettis™ VOS-PAC is a pre-engineered, pre-specified turnkey solution providing instant quotes, pricing & quick deliveries, quick access to related documents & remote maintainenance with QR Codes

Vanessa Series 30,000 for Ammonia Services

A triple offset valve with an integral-to-body valve seat & optimized seating angles. Comes with a powered actuator. Configurable by power source, size & function

Frequently Asked Questions About Blue Hydrogen

Blue hydrogen is produced from natural gas or coal using steam methane reforming (SMR) or autothermal reforming (ATR).

Hydrogen production is often designated by color, which indicates the process’s environmental ramifications. Green hydrogen utilizes non-carbon sources of electricity, such as wind and solar. Blue hydrogen is produced from natural gas or coal with relatively limited greenhouse emissions. It is currently less costly and more commercially viable than fully renewable green hydrogen.

Some benefits of blue hydrogen are:

The primary concerns for blue hydrogen producers and users are safety, efficiency and reliability. Ensuring purity, precisely controlling process units, achieving the highest possible CO2 capture rates, optimizing storage capacity, and managing energy and maintenance costs are all necessary to make sure a steady supply of hydrogen is available to meet quickly rising demand.

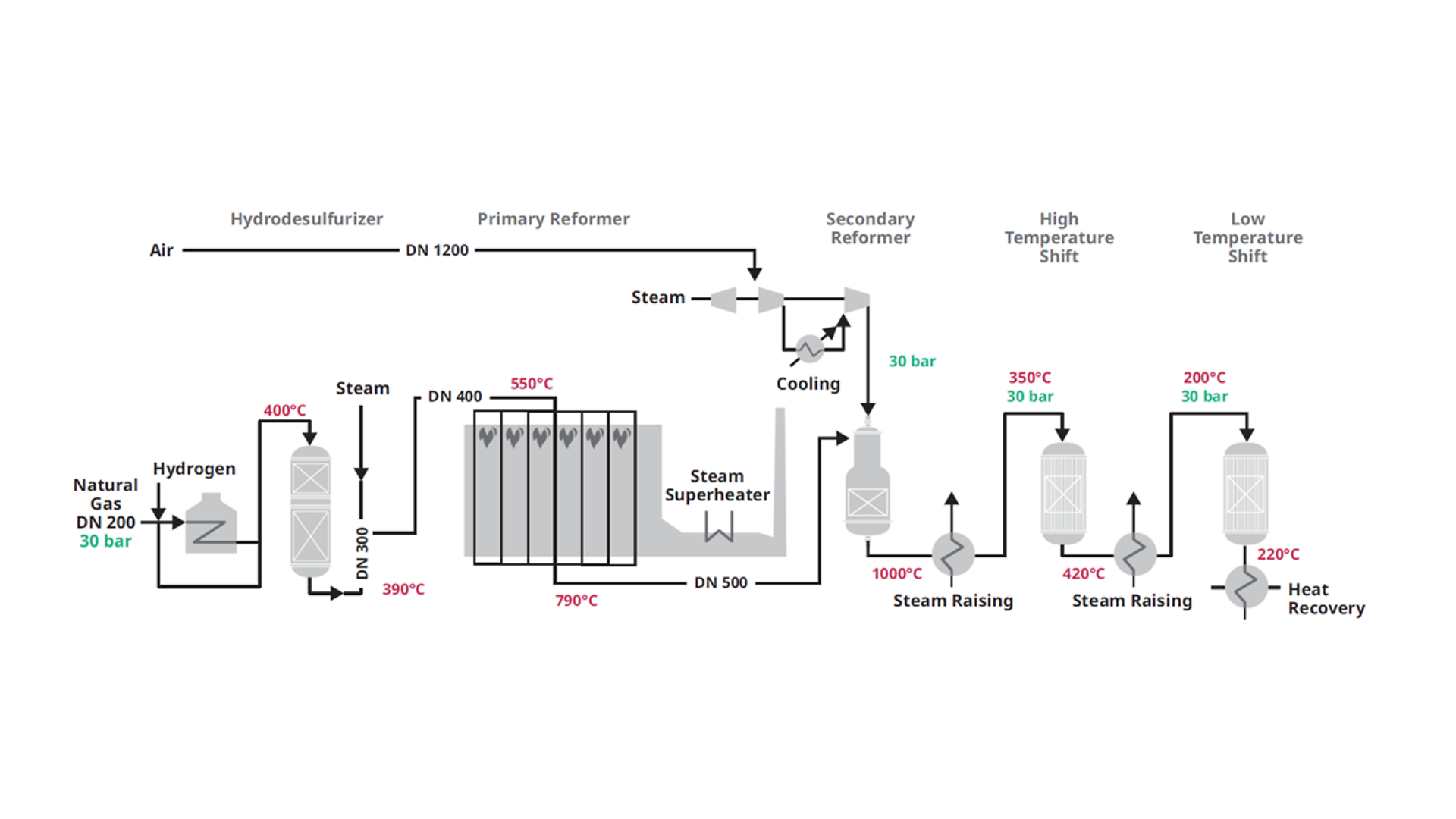

Steam methane reforming (SMR) is the most common method of manufacturing blue hydrogen from natural gas. It applies steam under tremendous temperature and pressure to a chemical catalyst that separates hydrogen from feedstock and binds carbon to oxygen atoms from water, forming CO2 as a byproduct. Throughput and efficiency depend on maintaining an optimal ratio of steam-to-carbon entering the reformer, protecting the catalyst from coking and managing energy usage.

Shortened as CCUS, it refers to greenhouse emissions reduction technologies applied to the energy value chain. The common CCUS methods in blue hydrogen production are:

Valves with low-emissions packing solutions help mitigate fugitive emissions of Methane and CO2 in SMR units, leading to low maintenance and long service life. Butterfly valves lab-tested in up to one million cycles allow for optimal catalyst bed control. Automation using advanced process control systems, online asset monitoring & mass flow meters can improve the efficiency and profitability of SMR units by controlling the steam-to-carbon ratio. Continuous chemical composition analysis can extend the life of the catalyst. Energy management information systems (EMIS) make it easier for hydrogen plants to hit optimal steam and electricity usage targets.